From novices playing with their first electronic kits to seasoned pros designing complex circuits, every electronics enthusiast knows the value of a good soldering job. Soldering is the art and science of joining two metal pieces using a filler material, ensuring electrical continuity and strength. At the heart of this process is the soldering station, and the quality of this equipment can make all the difference in your projects. But why exactly is a quality soldering station so indispensable? Let’s delve into the details.

Precision Matters in Miniature Worlds

Electronics components are shrinking, with resistors, capacitors, and integrated circuits getting tinier. This miniaturization demands precision. A quality soldering station provides the control and stability needed to solder these small components accurately. An unstable hand or a soldering iron with fluctuating temperatures can cause components to burn out or create short circuits, ruining hours of work.

Consistency is Key

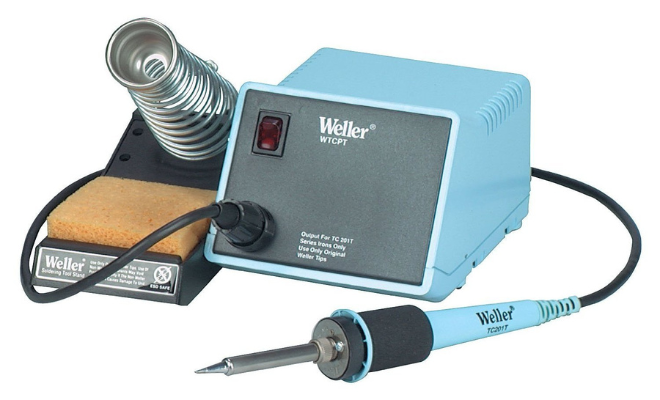

Unlike rudimentary soldering irons, advanced soldering stations come with temperature control features. This ensures that the tip of the soldering iron remains at a consistent temperature, vital for a steady and even solder flow. Inconsistent temperatures can lead to cold solder joints, which are weak and can cause circuit failures. When working with sensitive components, especially ICs, maintaining a consistent temperature is crucial to prevent overheating and damage.

Longevity and Durability

Investing in a quality soldering station means investing in a tool that lasts. Superior soldering stations are built with robust materials designed to withstand regular use. Their tips are often made of high-grade metals, ensuring minimal wear and tear over time. In contrast, cheaper variants might require frequent tip replacements, increasing the overall cost in the long run.

Enhanced Safety

Safety is paramount in electronics. Quality soldering stations come with safety features such as insulation, grounded plugs, and stands to hold the hot iron. These features minimize the risk of burns, shocks, or any other accidents during the soldering process.

The Role of Ballasts for Lights

One might wonder, what do “ballasts for lights” have to do with soldering? Ballasts are essential components in fluorescent lighting systems, ensuring the right amount of current flows through the lamp. Constructing or repairing ballasts requires a series of delicate soldering tasks, from attaching tiny components to connecting larger pieces of metal.

With a subpar soldering station, you risk creating weak joints, leading to flickering lights or even the risk of ballast failure. A quality soldering station ensures that these crucial components are constructed or repaired with utmost precision, ensuring efficient and safe operation of the lighting system.

Adaptability and Versatility

Modern soldering stations often come with interchangeable tips and advanced features. This versatility allows enthusiasts to adapt their tool to the task at hand, whether it’s working on a tiny PCB or repairing a chunky power adapter. The ability to switch between different tips or adjust the temperature to suit various solder types makes a quality station an indispensable tool in the electronics toolkit.

Improved User Experience

Lastly, the user experience cannot be ignored. Quality soldering stations are ergonomically designed, providing comfort during extended soldering sessions. Features such as digital displays, intuitive controls, and ergonomic grips enhance the overall soldering experience, making the task more enjoyable and less of a chore.

Conclusion

For every electronics enthusiast, from the amateur tinkerer to the professional engineer, a quality soldering station is not just a luxury—it’s a necessity. It ensures precision, consistency, and safety, factors that can significantly impact the outcome of any project. When working with essential components, such as ballasts for lights, the margin for error is minimal, and only a top-notch soldering station can guarantee the desired results. Investing in a good soldering station is, in essence, investing in the success and longevity of your electronics projects.