When working with electrical systems, whether for residential, industrial, or commercial purposes, having a reliable and safe method to connect wires is essential. Traditional methods, such as using screw terminals or crimp connectors, have been commonly used for years. However, in recent times, push-in wire connectors have become a popular and ideal choice for those looking for a quicker, more secure, and more efficient connection solution. In this blog, we will explore push-in wire connectors, their advantages, and how to properly use them with standard wire for various electrical applications.

What Are Push-In Wire Connectors?

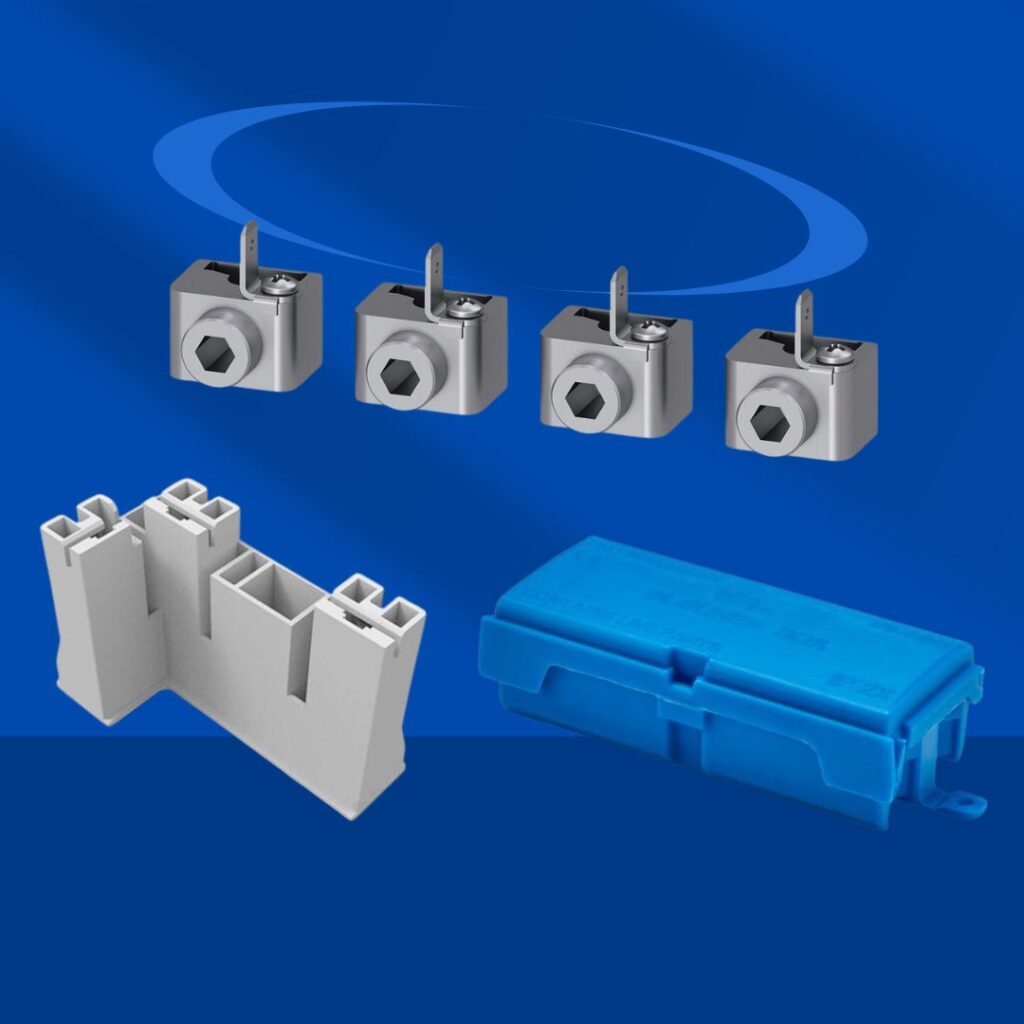

Push-in wire connectors, as the name suggests, are designed to securely connect wires without the need for any special tools or crimping. These connectors work by simply pushing the wire into the connector’s terminal, which then locks the wire in place through a spring mechanism inside the connector. They are ideal for use in applications where a fast, reliable, and tool-free connection is required.

Push-in wire connectors are especially valuable for residential electricians, DIYers, and even industrial applications where reliability and ease of use are essential. These connectors offer an innovative solution for ensuring a solid electrical connection without the hassle of tightening screws or using crimping tools.

Advantages of Push-In Wire Connectors

There are several reasons why push-in wire connectors are gaining popularity in electrical work, particularly in the UK market. Let’s explore these advantages:

1. Ease of Use

Push-in wire connectors are incredibly easy to use, even for beginners. The main advantage is that they don’t require specialized tools or expertise. Unlike traditional screw terminals, where you need to twist wires around a screw, push-in connectors simply require you to push the wire into the connector’s terminal. The spring mechanism inside holds the wire firmly in place, ensuring a secure connection.

2. Time-Saving

One of the biggest benefits of push-in wire connectors is how much time they save. Since the process is tool-free and involves no complicated steps, installation is faster than traditional methods. This makes push-in connectors ideal for both large-scale electrical installations and smaller DIY projects where time efficiency is critical.

3. Reliability and Safety

Push-in wire connectors are designed to provide secure and durable connections, which are crucial for ensuring the safety of your electrical system. The internal spring mechanism provides a strong grip on the wire, ensuring that the wire doesn’t slip out or become loose over time. This reliability reduces the risk of electrical failure or fire hazards.

4. Compact and Neat

Push-in wire connectors are compact and have a small form factor, making them an ideal choice for tight spaces where traditional screw terminal connections might be difficult to manage. They help keep wiring installations neat and organized by reducing the need for bulky tools and additional components.

5. Versatility

These connectors are versatile and can be used with a variety of wire types, including solid and stranded wire. Push-in wire connectors are available in different sizes, making them suitable for a wide range of electrical applications. From home wiring projects to more complex industrial systems, these connectors can provide a reliable solution.

How to Use Push-In Wire Connectors with Standard Wire

Using push-in wire connectors with standard wire is straightforward, but it’s important to follow the correct steps to ensure a proper and safe connection. Here is a simple guide on how to use push-in wire connectors for your electrical projects:

Step 1: Prepare the Wire

Before inserting the wire into the connector, make sure that the wire is stripped of insulation. Use a wire stripper to remove about 10-12mm of insulation from the end of the wire. It’s essential not to strip too much or too little of the insulation to ensure the wire fits properly inside the connector and forms a secure connection.

Step 2: Select the Right Connector Size

Push-in wire connectors come in different sizes depending on the gauge (thickness) of the wire being used. Be sure to select a connector that matches the wire size. If the wire is too large for the connector, it won’t fit, and if it’s too small, it may not be held securely inside the connector. Always check the manufacturer’s specifications for the appropriate wire size range for each connector.

Step 3: Insert the Wire into the Connector

To insert the wire into the push-in wire connector, gently push the stripped end of the wire into the terminal. There should be a noticeable resistance as the wire slides into the connector, indicating that the internal spring mechanism is securing the wire in place. Once the wire is fully inserted, check to ensure that it’s tightly locked inside the connector.

Step 4: Test the Connection

Once the wire is securely inserted into the connector, give it a slight tug to make sure it is firmly held. If the wire slips out, the connector may not have been installed properly, and the connection could be unsafe. In this case, remove the wire and reinsert it to ensure a secure fit.

Step 5: Connect Multiple Wires (if applicable)

In some cases, you may need to connect multiple wires to a single connector. Many push-in wire connectors allow for this, making it easy to join several wires together in one compact, secure connection. Just make sure that each wire is inserted correctly and securely.

Applications of Push-In Wire Connectors

Push-in wire connectors are widely used in a variety of applications, ranging from household electrical wiring to more advanced commercial and industrial uses. Let’s explore some common areas where these connectors are most beneficial:

1. Residential Wiring

In homes, push-in wire connectors are ideal for use in lighting switches, outlets, and appliance installations. These connectors allow for quick and secure connections in various electrical systems, making them especially popular among DIY electricians.

2. Industrial Control Systems

In industrial settings, push-in wire connectors are used to wire control panels, machinery, and other electrical equipment. Their compact design and reliability make them perfect for use in environments where space is limited and secure electrical connections are crucial for operational safety.

3. Automotive Applications

Push-in connectors are also used in automotive wiring, where they help create fast, reliable connections in the vehicle’s electrical system. The ability to easily connect multiple wires in tight spaces without using specialized tools is particularly useful in automotive electrical repairs and customizations.

4. Telecommunications and Networking

For applications involving communication systems, networking devices, or data transmission panels, push-in wire connectors offer a streamlined way to make connections. Their reliability ensures that signals are not interrupted, making them ideal for telecom installations and server rooms.

Push-In Wire Connectors in the UK Market

In the UK, push-in wire connectors are becoming increasingly popular due to their ease of use, time-saving nature, and reliability. As electricians and DIY enthusiasts look for simpler, more efficient solutions to their wiring projects, push-in connectors provide a versatile option that meets their needs. Available in a range of sizes and configurations, these connectors are widely used for both residential and commercial applications.

Enrgtech offers high-quality push-in wire connectors suitable for a variety of electrical projects. Whether you’re working on a home renovation, industrial machinery, or automotive wiring, these connectors ensure you have a reliable and secure connection for your electrical systems.

Conclusion

Push-in wire connectors offer an ideal solution for anyone looking for a fast, secure, and efficient method of connecting wires. Their ease of use, combined with a range of advantages such as reliability, versatility, and time-saving features, make them an excellent choice for residential, commercial, and industrial applications. By following simple steps and selecting the appropriate connectors for your wire size, you can achieve secure and long-lasting electrical connections for all your projects.