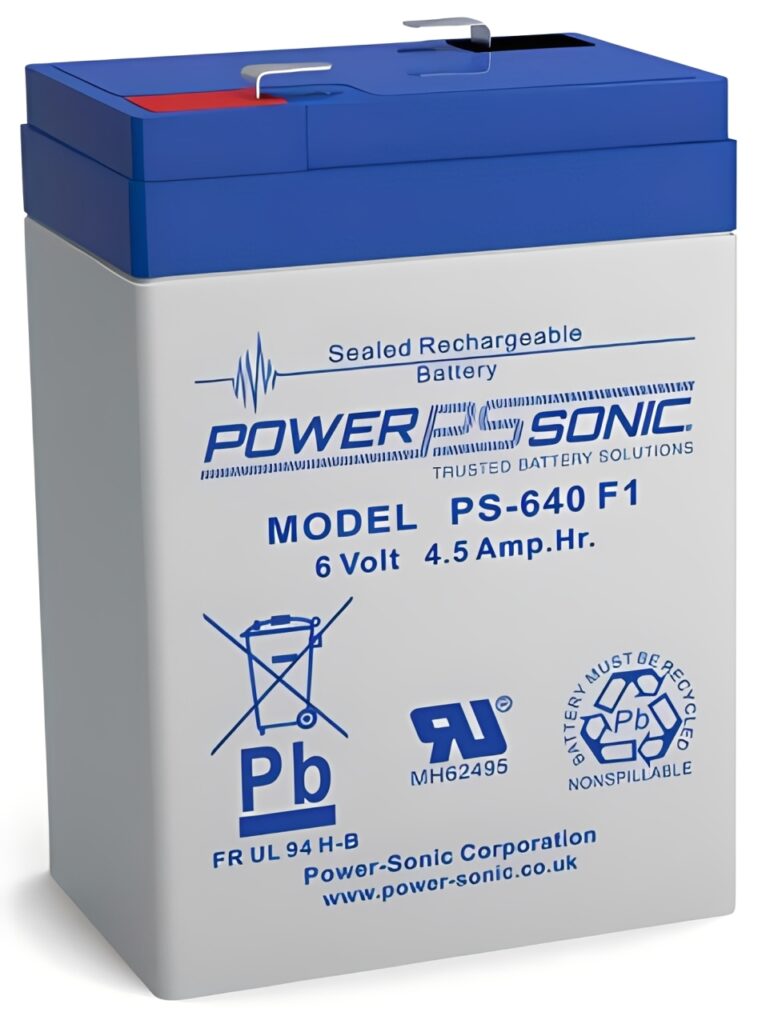

Rechargeable Sealed Lead Acid Battery

A Rechargeable Sealed Lead Acid Battery is a dependable, maintenance friendly power source used when you need steady backup energy and predictable performance. It is common in UPS systems, emergency lighting, alarms, mobility devices, and many electronics that must stay online during power loss.

Because it is sealed, it is designed to operate with minimal electrolyte handling, while still delivering strong surge current. As a result, it remains a practical choice for many industrial and everyday applications.

What a sealed lead acid battery is and why it matters

Sealed lead acid batteries are a type of lead acid chemistry built to reduce free liquid electrolyte exposure. Most are VRLA batteries, which means they regulate internal gas and typically recombine oxygen inside the cell.

This design supports safer indoor use and easier installation in cabinets, racks, and equipment enclosures. Therefore, it fits well in systems where space, safety, and reliability matter more than ultra light weight.

Common SLA types you will see

While many people say “sealed lead acid” as one category, two designs are especially common:

- AGM (Absorbent Glass Mat)

- Gel

Both are sealed styles, yet they differ in how electrolyte is held. In practice, AGM often supports higher current bursts, while Gel can perform well in deeper cycling use cases when charged correctly.

How a Rechargeable Sealed Lead Acid Battery works

Inside the battery, lead based plates react with electrolyte to store and release energy. During discharge, the reaction produces electricity that flows through your load and returns through the circuit. During charging, the reaction reverses and restores the plates.

Because the battery is sealed, internal pressure management is important. That is why correct charging voltage and temperature control are critical for long life and stable capacity.

Why charging control is part of performance

SLA batteries are sensitive to overcharge heat and undercharge sulphation. So, the charger and its settings are not optional details. A good charger limits voltage, manages current, and adjusts behaviour when thermal conditions change.

In real installations, thermal factors can also affect connected parts like cables, connectors, contactors, fuses, and switches. Consequently, battery selection should consider the whole power path, not only the battery label.

Key specifications to evaluate before buying

Choosing the right unit starts with understanding the specs that actually control real world results.

Capacity and runtime

Capacity is usually rated in amp hours at a defined discharge rate. However, runtime changes with load current and temperature. If your device draws higher current, effective capacity drops.

To estimate quickly, you can consider:

- Load power and expected backup duration

- Battery voltage and capacity

- Conversion losses in controllers, inverters, or DC regulators

Voltage and form factor

Common options include 6V and 12V blocks, and there are many sizes for the same voltage. Measure the available space, then match the battery dimensions and terminal style to your enclosure and connectors.

Also check that your electronics accept the battery voltage range during discharge. Some controllers and sensors become unstable as voltage falls, especially if they power LEDs, microcontrollers, or other sensitive electronics.

Cycle life and design intent

Not all SLA batteries are built for the same job. Some are optimised for standby float service, while others are designed for cycling.

If you need frequent discharge and recharge, pick a model specified for deep cycle use. Otherwise, a standby focused unit is often better for UPS and alarm panels.

Where these batteries are used in real products

A Rechargeable Sealed Lead Acid Battery is popular because it is predictable, widely supported, and easy to integrate.

Typical product and system uses include:

- UPS backup for desktops, network gear, and laptops in docking setups

- Emergency lighting and exit signage

- Security and fire alarm panels with sensors and sirens

- Access control systems using contactors and switches

- Mobility and light traction devices

- Test benches and portable tools requiring stable DC power

In many of these systems, the battery is connected through protective elements. For safety and reliability, you will often see fuses, relays, contactors, and robust connectors placed close to the battery terminals.

How to select the right battery for your application

Start with your load profile, then confirm compatibility across the full electrical chain.

Match the electrical demands first

Focus on:

- Required voltage under load

- Peak current, especially for motors, inverters, and high brightness LEDs

- Expected runtime

- Standby versus deep cycle behaviour

If your system includes microprocessors, microcontrollers, or sensitive control boards, ensure undervoltage behaviour is managed. A battery that sags too quickly can cause resets and false sensor readings.

Confirm installation details

Before finalising, check:

- Terminal type and orientation

- Cable gauge and length for voltage drop control

- Connector rating for current and heat

- Ventilation and spacing for thermal stability

- Mounting position guidance from the battery manufacturer

Because heating accelerates ageing, use sensible routing for cables and avoid tight bundles near thermal pads, transformers, or other hot components. Also keep oils and chemical contaminants away from terminals and cases, since they can degrade plastics and cause tracking.

Charging and maintenance tips that extend battery life

Even though sealed lead acid is often called maintenance free, it still needs correct charging and sensible use.

Practical habits that protect lifespan include:

- Use a charger made for sealed lead acid chemistry

- Avoid deep discharge whenever possible

- Recharge soon after use to reduce sulphation risk

- Keep the battery cool and away from sustained heat sources

- Store fully charged and top up on schedule if kept in storage

Temperature matters more than most people expect

Battery chemistry slows down in cold and ages faster in heat. Therefore, thermal management is a performance feature, not a comfort detail. If your unit sits in an enclosure with power electronics, provide airflow paths or thermal isolation where possible.

If your design uses thermal pads for other components, ensure the battery is not pressed against hot surfaces. Small changes in placement can reduce temperature rise and improve service life.

Safety and protection practices for reliable operation

A Rechargeable Sealed Lead Acid Battery can deliver high current instantly. So, protection and handling matter.

Use these best practices:

- Fit an inline fuse close to the positive terminal

- Choose switches and contactors rated for DC current

- Use connectors designed for the expected load

- Keep terminals tight and clean to avoid resistance heating

- Inspect cables for wear, especially near bends and grips

When building or servicing systems, remove metal jewellery and use insulated tools. Also confirm polarity before connecting, since reverse polarity can damage controllers and power stages instantly.

Troubleshooting performance problems

If a battery seems weak, the issue may be battery condition, charging method, or the surrounding electrical path.

Common causes include:

- Undercharging due to incorrect charger voltage

- Overcharging that increases heat and dries internal electrolyte

- Loose connectors creating voltage drop

- Undersized cables causing warm spots and reduced runtime

- Aged battery that no longer holds capacity

If your system includes sensors, alarms, or control boards, watch for intermittent resets during load changes. That symptom often points to voltage sag under peak current rather than total failure.

Sustainability and end of life handling

Lead acid batteries are among the most recycled battery types in many regions. Still, safe disposal matters.

When replacing a unit:

- Return the old battery through proper recycling channels

- Avoid opening the case or attempting to add fluid

- Store used batteries upright and protected from short circuits

This approach supports safer workplaces and responsible materials recovery.

Key takeaways for buyers and system builders

A Rechargeable Sealed Lead Acid Battery remains a strong choice for backup power, standby systems, and many industrial electronics because it is proven, widely compatible, and cost effective. If you match capacity, charging method, and installation conditions, you can achieve stable runtime and long service life while maintaining safety through correct fuses, connectors, cables, and protective switching.