Introduction

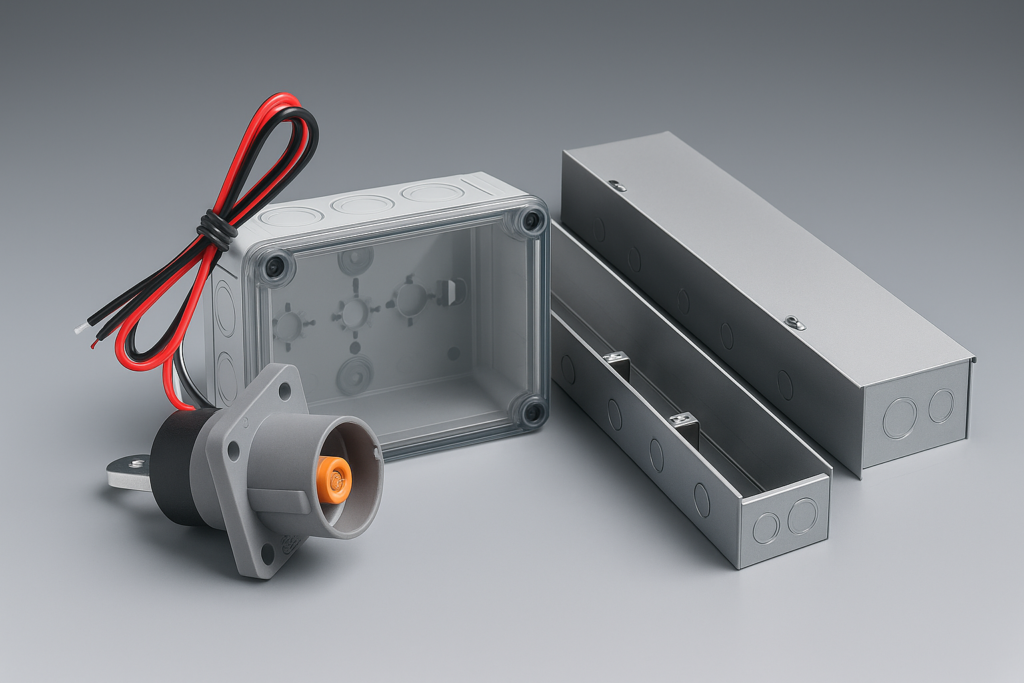

In today’s interconnected world of electronics and electrical installations, the safety and reliability of wiring systems cannot be compromised. Whether in industrial automation, residential projects, or commercial facilities, components such as a junction box electrical system, electrical cable connectors, and secure junction box wiring form the backbone of efficiency and safety. These elements not only simplify complex installations but also ensure compliance with electrical standards, reduce hazards, and enhance long-term system performance.

This blog explores the role of junction boxes, connectors, and wiring methods in modern electronics and electrical infrastructures.

What Is a Junction Box Electrical System?

A junction box electrical system acts as a protective enclosure for housing wire connections. Typically made of metal, polycarbonate, or thermoplastic materials, junction boxes prevent accidental contact with live wires while protecting them from dust, moisture, and mechanical damage.

In electronics and electrical engineering, junction boxes provide:

- Safety: Shielding users and technicians from electrical shocks.

- Organization: Grouping multiple wire connections neatly.

- Protection: Preventing short circuits or overheating caused by loose connections.

- Scalability: Allowing additional circuits to be added without compromising the system.

By acting as a central hub, the junction box ensures that electrical and electronic systems remain safe and manageable.

Importance of Electrical Cable Connectors

While junction boxes protect connections, electrical cable connectors serve as the linking components that join wires and circuits together. Their design ensures low resistance, high conductivity, and long-lasting durability.

In electronic systems, connectors are vital because they:

- Ensure Consistent Current Flow: Minimizing energy losses and improving circuit efficiency.

- Support Versatility: Available in multiple types, including crimp connectors, screw terminals, circular connectors, and modular plugs.

- Provide Safety: Prevent arcing, overheating, and potential short circuits.

- Enhance Maintenance: Allow quick disconnection and reconnection for repairs or testing.

From control panels and consumer electronics to automotive systems and industrial machines, electrical cable connectors are indispensable for maintaining reliable wiring systems.

Junction Box Wiring and Its Role in Electronics

Proper junction box wiring is critical in both residential and industrial environments. Incorrect wiring may lead to dangerous outcomes such as circuit overloads, electrical fires, or costly downtime in production facilities.

Some best practices in junction box wiring include:

- Using the Right Connectors: Ensuring compatibility with wire gauge and material.

- Organized Cable Management: Grouping and labeling wires inside the box for easy identification.

- Following Electrical Codes: Adhering to IEC, NEC, or BS standards for safety and compliance.

- Testing Continuity: Using electronic test equipment like multimeters or insulation testers to verify secure connections.

In electronics labs or automation systems, junction box wiring ensures that sensors, PLCs, power supplies, and actuators remain reliably connected to the main control systems.

Applications Across Industries

• Industrial Automation

Factories rely on junction box electrical systems to house wiring for motors, drives, and control panels. Electrical cable connectors link sensors, controllers, and actuators, ensuring precise electronic communication.

• Residential and Commercial Buildings

In homes and offices, junction boxes protect household wiring, while connectors link lighting systems, appliances, and electronic equipment safely and efficiently.

• Data Centers and Networking

Cable connectors such as RJ45 and fiber optic connectors manage high-speed data transfer. Junction boxes secure structured cabling systems, reducing electromagnetic interference.

• Automotive Electronics

Cars and trucks use junction boxes for wiring harnesses, while specialized connectors ensure safe operation of electronic systems like infotainment, lighting, and engine management.

• Renewable Energy Systems

In solar power and wind turbine installations, junction boxes protect circuits exposed to outdoor conditions, while electrical cable connectors provide reliable current flow between panels, batteries, and inverters.

Advantages of Using Proper Junction Boxes and Connectors

• Safety and Compliance

A well-designed junction box electrical system combined with secure connectors reduces risks of electrical hazards, ensuring compliance with international standards.

• Long-Term Reliability

High-quality connectors prevent corrosion and ensure long-term conductivity. Proper junction box wiring reduces wear and tear caused by environmental factors.

• Easy Maintenance and Expansion

Technicians can access connections quickly within junction boxes, making upgrades and repairs more efficient. Electrical cable connectors simplify replacements without rewiring the entire system.

• Cost Efficiency

By protecting wires and extending the lifespan of electrical installations, junction boxes and connectors reduce downtime and minimize replacement costs.

Trends in Junction Box Electrical and Connector Technology

The electronics industry continues to innovate, and even traditional components like junction boxes and connectors are evolving. Key trends include:

- Smart Junction Boxes: Integration of IoT sensors to monitor load, temperature, and connectivity in real time.

- Miniaturization of Connectors: Required for compact electronic devices and consumer electronics.

- Eco-Friendly Materials: Manufacturers increasingly use recyclable thermoplastics and low-carbon materials.

- Improved Weather Resistance: IP-rated enclosures and corrosion-resistant connectors support outdoor electronics and renewable energy applications.

Maintenance Best Practices

To maintain efficiency and safety in junction box wiring and connector systems:

- Inspect wiring connections regularly for wear or corrosion.

- Ensure connectors are tightly fastened and compatible with the conductor type.

- Test with electronic instruments to detect continuity and insulation resistance.

- Replace damaged boxes or connectors immediately to prevent hazards.

Conclusion

The trio of junction box electrical systems, electrical cable connectors, and proper junction box wiring ensures that electronic and electrical systems remain safe, efficient, and future-ready. From residential circuits to advanced industrial automation, these components act as the foundation of connectivity and protection.

In an era where electronics drive innovation in every field, reliable wiring practices are non-negotiable. By using the right connectors, protective junction boxes, and standardized wiring techniques, businesses and households alike can ensure long-lasting performance, safety, and adaptability in their electrical networks.